先進封裝製程

Advanced Packaging Process

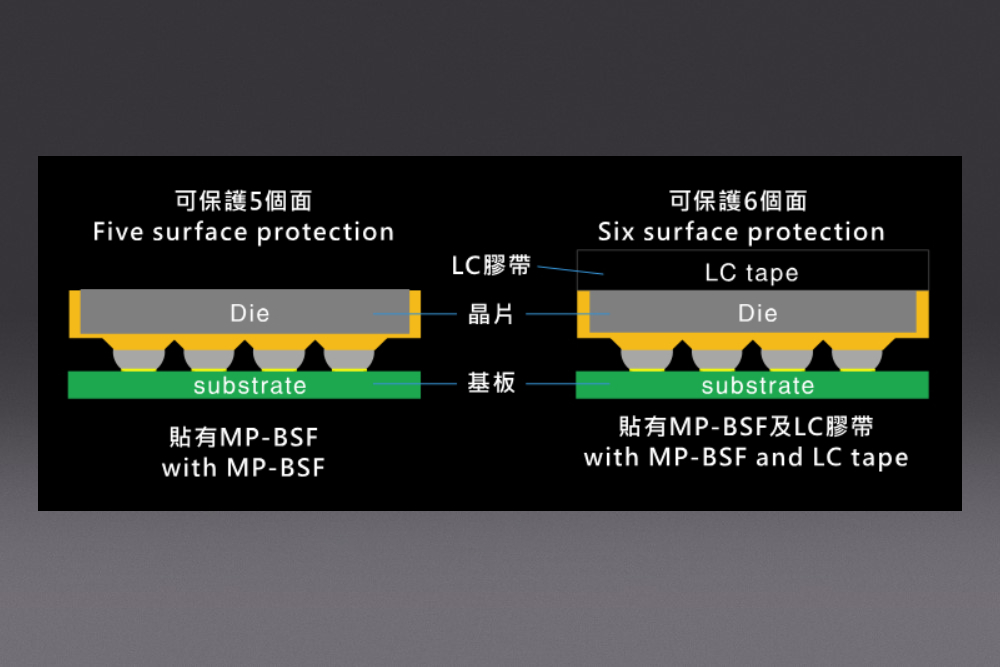

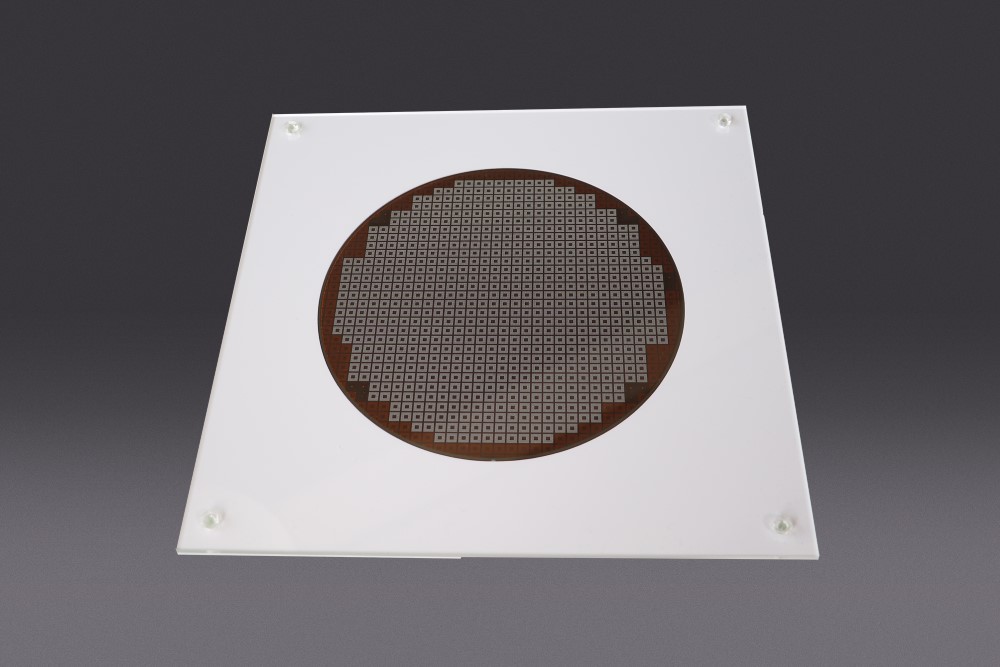

具備多重保護功能的錫球保護膠膜 (MP-BSF)Multiple Protect Bump Support Film (MP-BSF)

- 將具備多重保護功能的錫球保護膠膜貼於切半之晶圓上,可有5個面的保護功能

- 與LC膠帶貼合,則可有6個面的保護功能

- Five surface protection is possible by laminating MP-BSF to a half-cut wafer

- Six surface protection is possible by combining with LC tape

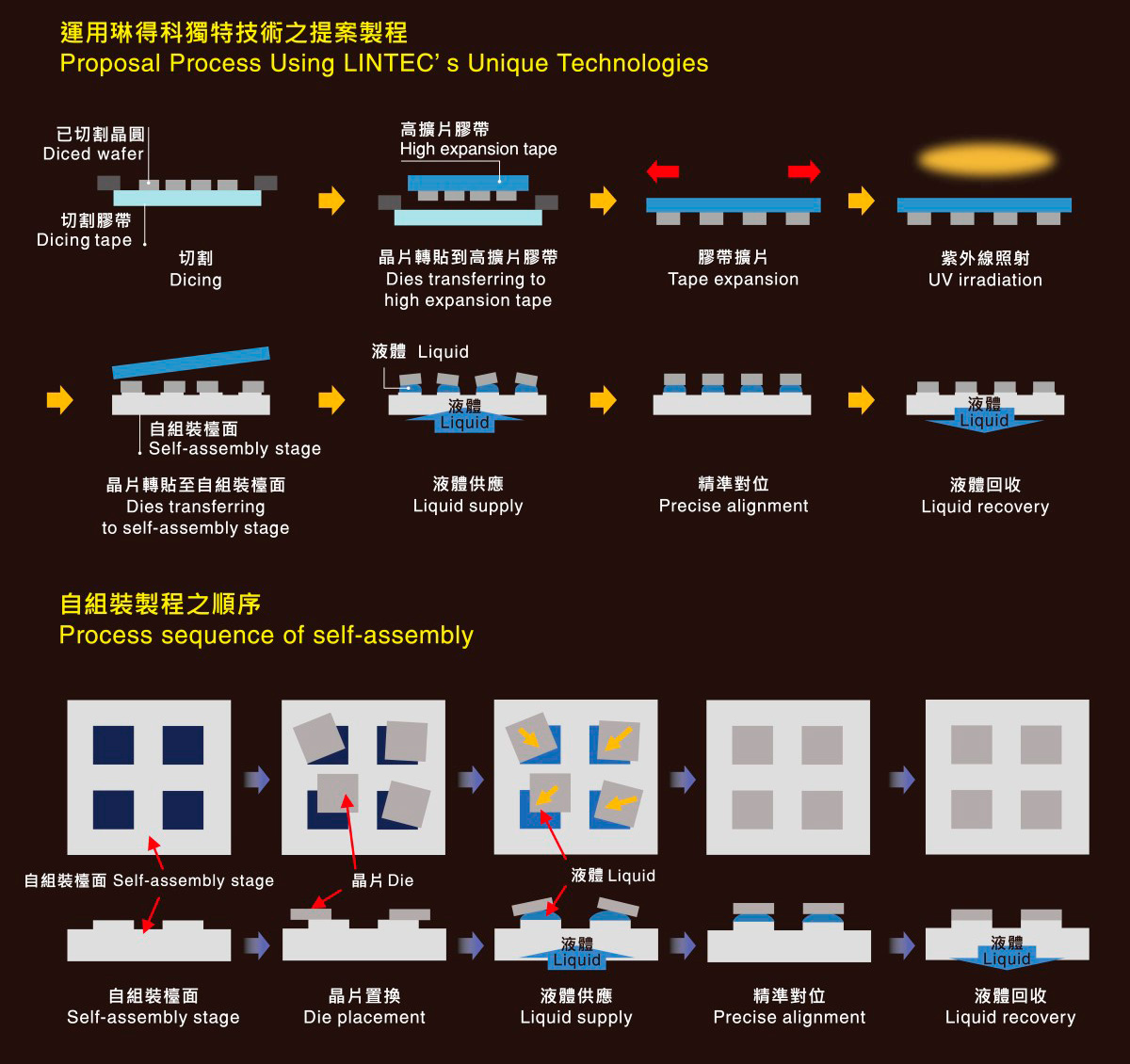

適用於扇出型晶圓級封裝之晶片置換技術 擴片製程 / 自組裝製程Die Placement Technologies for FO-WLP Expansion Process / Self-Assembly Process

琳得科提案的新製程結合膠帶擴片及自組裝技術,以實現精準的置換能力及優良的產出率。

To achieve both high placement accuracy and high throughput, LINTEC proposes a novel process that combines tape expansion technology and self-assembly technique.

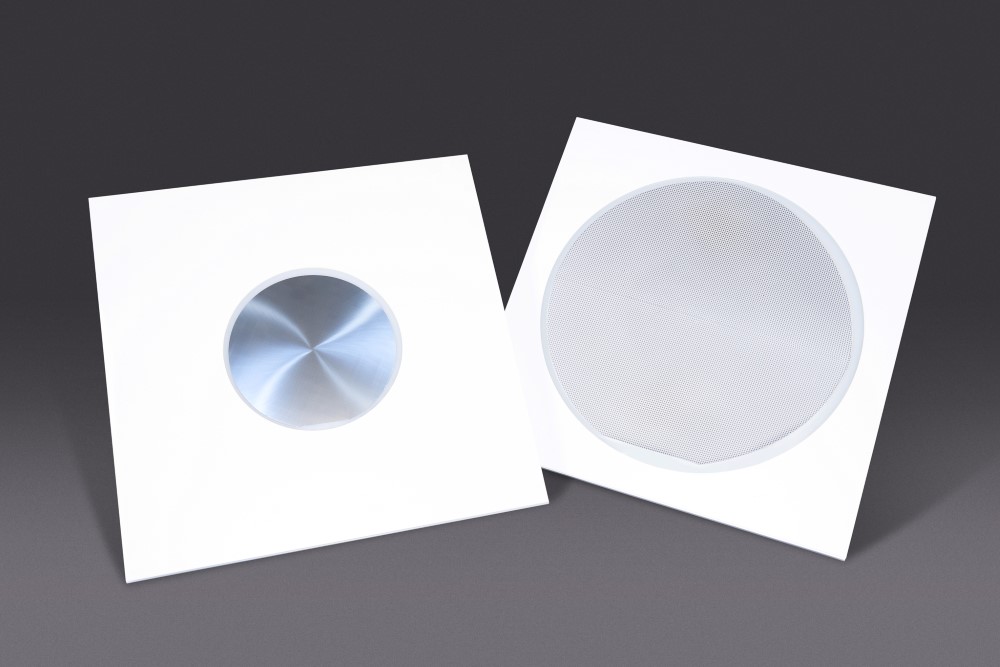

紫外線硬化型 適用於高溫製程之耐熱膠帶UV Curable Heat-resistant Tape

-

適用於各種高溫製程中,固定、保護及搬運工作片之膠帶

- 可依客戶需求,提供不同款式之紫外線硬化型耐熱膠帶

- 具優良穩定性,高溫製程後容易撕離、不留殘膠 Tape offers superior performance with regards to temporary fix, protection and handing during various high temperature processes.

- Provide different types of UV curable heat-resistant tapes according to customer needs

- Excellent stability, easy to peel off and no adhesive residue after high temperature process

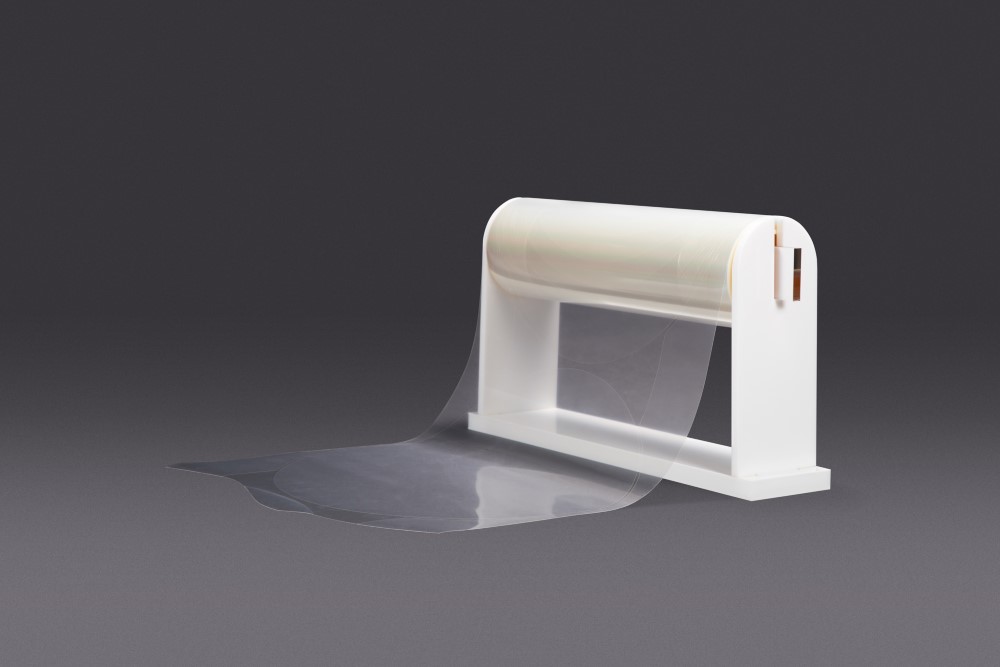

錫球保護膠膜Bump Support Film

-

錫球保護膠膜可應用於錫球晶圓,在半導體後段製程的不同步驟中帶來以下好處:

- 保護焊接處以提升錫球晶片的可靠度

- 減少刀片切割時造成的晶圓表面崩裂

- 改善薄型晶圓/易碎晶圓的搬運性

- 可用於包覆錫球/銅柱

- 可用於提升晶片強度 BSF can be applied to bump wafers for benefits in different steps throughout the semiconductor back end process.

- Can increase the reliability of bump chips by protecting the solder joint

- Decreases top side chipping caused during blade dicing

- Can be used to improve handling of thin/brittle wafers

- Can be used to embed bumps/Cu pillars

- Can be used to improve die strength